Produkty Vexve ZMK

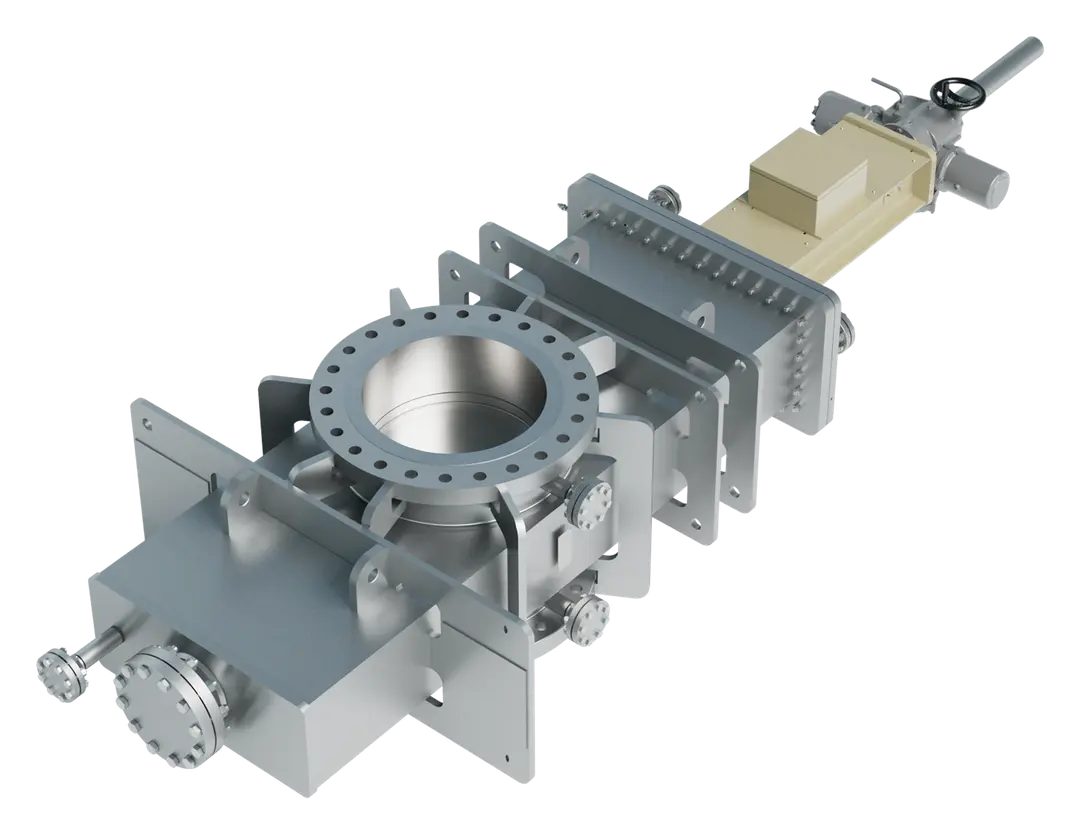

Dvoudeskové šoupátko – Ethylen

Výroba na míru podle platných norem a specifikací zákazníka. Osvědčená konstrukce průběžně optimalizovaná pro bezpečný a spolehlivý provoz v souladu s mezinárodními normami, jako jsou EN 13445, ASME B16.34 a API 6D.

Double disc metal seated isolation valves typically in sizes up to NPS 100” (2540 mm)

- Different kinds of actuation available (electric, hydraulic, pneumatic, manual)

- Customised design, acc. to governing standards and customer‘s specification

- Proven design continuously optimised for safe and reliable operation in compliance with international standards such as EN 13445, ASME B16.34 and API 6D

- Design for harsh environment e.g. MDMT lower than -40°C (-40°F), design temperature up to 650°C (1202°F), design pressure up to 18 bar (261 psi)

- Double-block and purge functionality in one valve

- Tight shut-off designed for zero leakage according to API 598 or ISO 5208

- Since the throughway is designed like a tube type passage in open valve position, it is ensured that the pressure drop across the valve can be neglected

- Steam purge in between the discs as well as in the valve body is required to always ensure that no coke fines resp. condensate can accumulate inside the valve during opening and closing, as well as in closed or open position

- Furthermore, metal-to-metal seating ensures there is no coke accumulation in the valve body

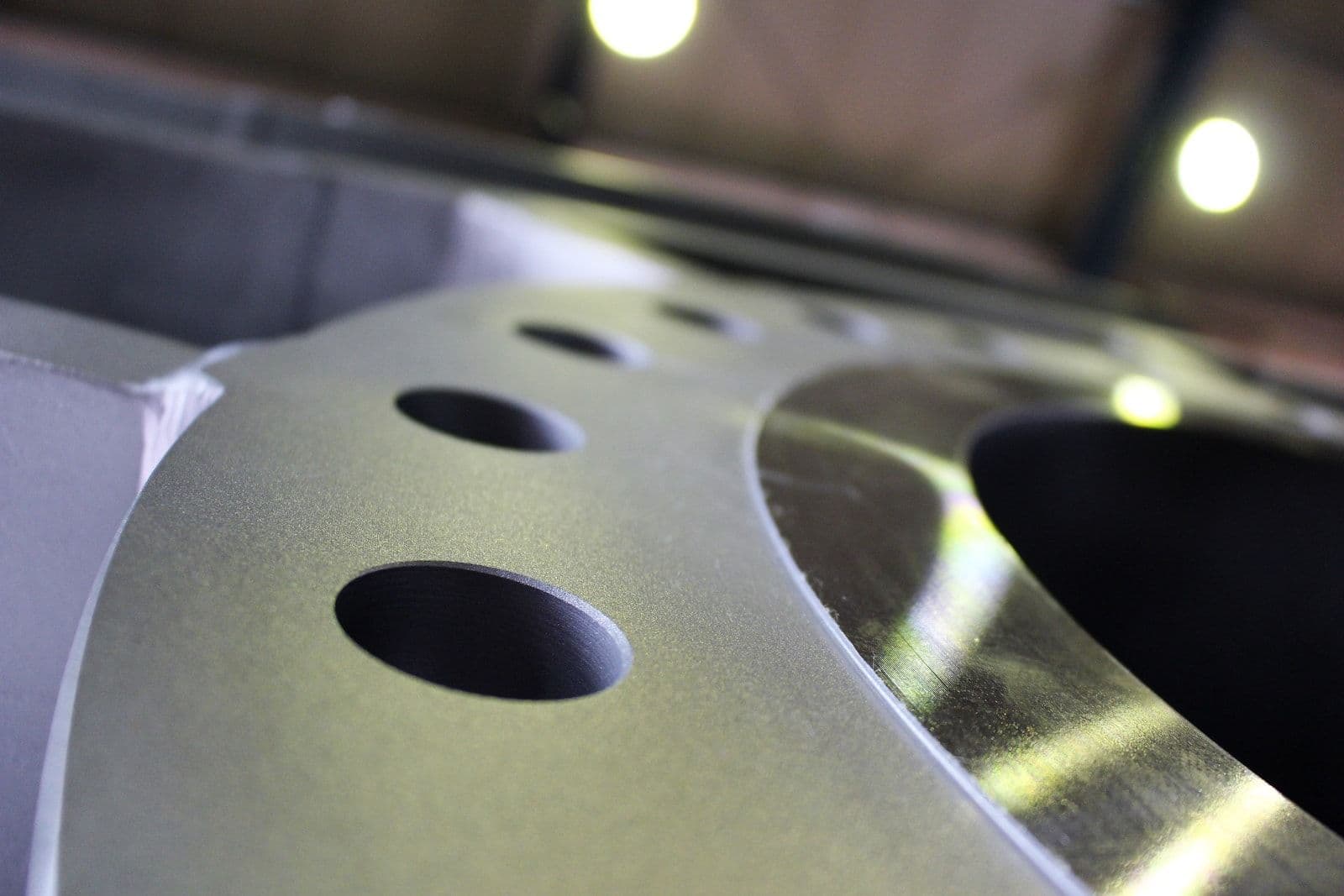

- The seat surfaces are solid hard metal to metal seats to minimise corrosion and wear, this ensures a long trouble free operation while providing absolutely tight shut-off

- Patented baffle technology to avoid 6 o´clock erosion on the downstream side. ONLY AVAILABLE FROM VEXVE ZMK!