And the hydrogen again!

Hydrogen is still one of the most discussed topics today, and it affects the whole world.

ARMATURY Group also cares about the environment and supports every project related to the transition to green. These projects include A hydrogen strategy for a climate-neutral Europe. And so, they are increasingly face with requirements for valves that will suit hydrogen operation.

It is important how the hydrogen behaves

One of the important things that a manufacturer of valves must perceive is the fact of how hydrogen behaves towards the materials from which industrial valves are made. In general, hydrogen has a smaller size of molecules and its throughput through imperfections of materials (e.g., micro cracks, unevenness, etc.) is much greater than, for example, in air.

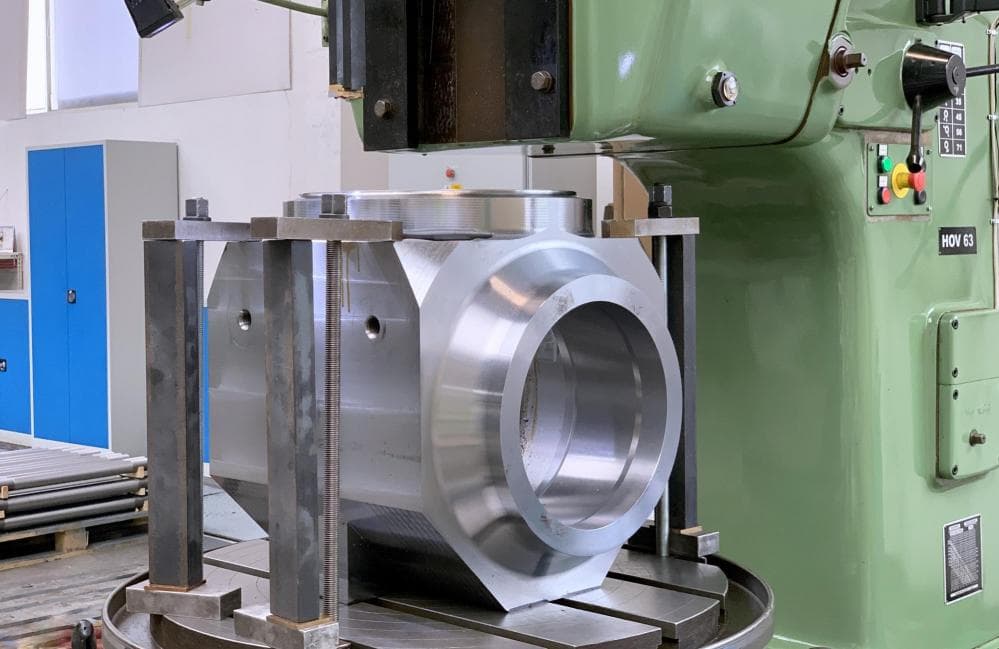

A forged than a cast input semifinished product is used as a much more suitable material. Since ARMATURY Group has most of its manufactured valves from these forged materials, it can be said that most of the production is suitable for use on a mixture of gases with hydrogen or pure hydrogen.

It is necessary to have a goal

The whole group, as well as individual companies, Vexve Armatury Group do not want to stay away and aim to gain a good position in the development of natural gas valves with added hydrogen. Which it declares in its strategy. All Vexve Armatury Group companies are members of hydrogen clusters. They can thus act and share their experience with colleagues from other European countries and participate with their comments in the harmonization of regulations and standards in the field.

Within the entire group, there is an effort to find as much as possible application of its existing products for processes where hydrogen is produced, transported or consumed. It does not have to be primarily hydrogen as an operating medium, but an input "semifinished product" from which hydrogen is then produced. A typical example can be ammonia or demineralized water for hydrolysis, etc.

ARMATURY Group is also represented in the working group of the European Committee for Standardization (CEN). Within this group, the problems of standards for valves for natural gas pipelines, to which hydrogen will be gradually added, are to be solved. The result of this activity is to be new EN standards, which will already reflect other technical requirements for valves used on mixtures of natural gas and hydrogen, and ultimately pure hydrogen.

Ready for a hydrogen future

Thanks to all these activities and experiences, ARMATURY Group is already ready for a hydrogen future. This is also thanks to the testing of existing types of valves, especially ball valves, which can be used to transport the working medium in various concentrations of hydrogens in natural gas. The durability of these valves is also important for ARMATURY Group. Therefore, the valves are exposed to the testing gas for several months to years during testing, under real operating conditions.

For more information:

Petr Heider, Technical Director