Czech metallurgical specials are heading to Slovakia

U. S. Steel Košice is an integrated steel company with more than 50 years of tradition and production capacity of 4.5 million tons of steel per year. The company, one of the largest in Slovakia, employs almost 11,000 people.

The blast furnaces ensure the transformation of iron ore raw materials into liquid metal within the metallurgical primary production plants. The three blast furnaces built in the late 1960s at U.S. Steel Košice have undergone significant modernization and are now among the most advanced in Europe in terms of technical equipment and production capacity.

This year, a major project called "Rebuilding of Heater No. 14 at Blast Furnace No. 1" is being implemented as part of the investment project. Construction began in early April and the work is scheduled to be commissioned by the end of December 2021.

For the reconstruction of OV14, Basic and Detail engineering by Danieli Corus is used. The general contractor of the construction is Termostav - Mráz, a company operating on domestic and foreign markets in the field of refractory linings, industrial assemblies, and special insulation.

ARMATURY Group will supply valves in the amount of million EUR

And it was with Termostav - Mráz that the ARMATURY Group concluded a subcontract for the technical solution, selection, and delivery of metallurgical valves for OV14.

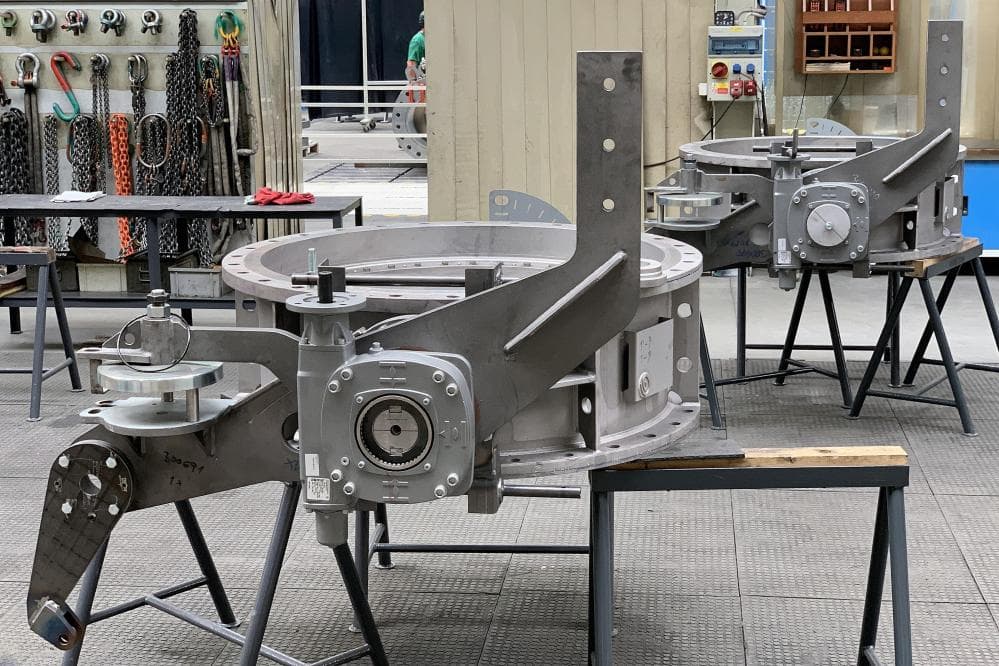

The subject of the contract is mainly the delivery of 13 pieces of metallurgical valves, as well as several other valves, counter flanges and seals. The delivery also includes functional testing and commissioning of the valves. ARMATURY Group offers a wide range of metallurgical and special valves, nine types of which are now manufactured and supplied to U.S. Steel Košice.

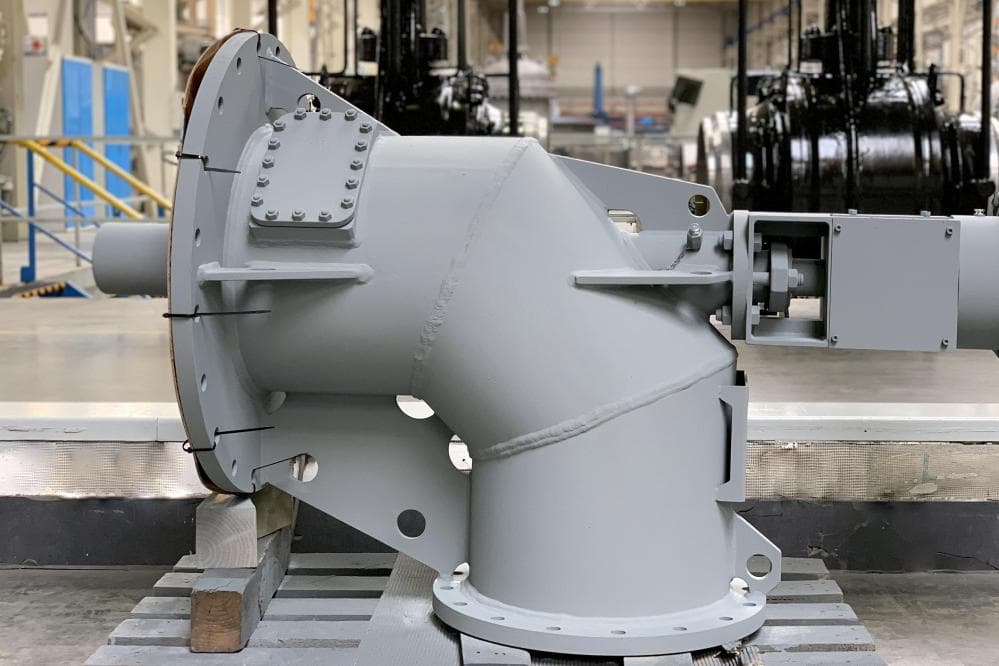

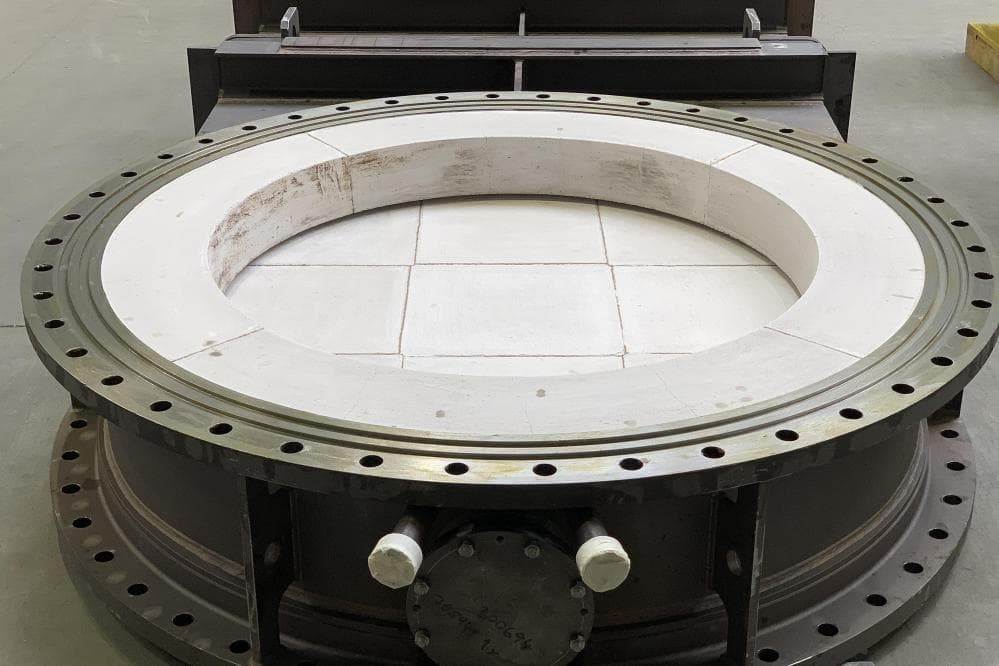

These are control valves type 124, butterfly safety valves type 118, butterfly double-lever valves type 141, hot-blast gate valve type 136, air check valve type KLAVZD, triple-eccentricity butterfly valve type 140A, relief valve type 125, rotary goggle valve type 117 and cooled spacer type 136.

The working media for these valves will be blast furnace gas, combustion gas, hot air, cold air and flue gas. The valves are supplied for temperatures in the range 200 °C to 1450 °C, depending on the valve type, and in sizes DN 400 to DN 1300. The contract also includes supply of metallurgical valves - spare parts for the initial equipment. The total volume of contract will amount to nearly 1 million euros!

For more information:

Zdeněk Kročil, Sales Director for Slovakia