HYDRO valves help produce clean energy

At ARMATURY Group we support sustainable development and production of green energy.

More often we produce and supply valves for the hydropower plant, where our butterfly valves and ball valves help with production of clean, green energy. Today, we will take a closer look at those valves for hydropower plants and their types.

What type of valves are they?

These are mainly ball valves and butterfly valves. The valves are controlled by a counterweight and hydraulic cylinder and they belong into the group of safety valves. Those valves are mostly used at hydropower plants, in front of the turbine. Due to this they are one of the elements, which secure the production of green energy.

In this way are our valves involved in sustainable development. You can find those valves in different places in the world, for example in Congo, Panama, Indonesia, the Philippines, and many other countries.

Due to the long-term cooperation with customers are our valves constantly developed and thanks to specific requirements of our customers and projects it is in most cases custom production, which goal is not only to satisfy the customer, but also to reduce the ecological footprint.

What is safety valve?

Safety valve can be opened or closed in case of emergency automatically, without an external power source. Valve can be opened or closed by counterweight, which is placed in the top position. In case of closing or opening the valve, the counterweight falls into bottom position, thanks to the gravitation.

From the bottom position is then moved to the top position by the hydraulic cylinder and lever. The counterweight is possible to close the valve, even without electrical energy, therefore the functionality and protection of the power plant equipment in all situations is ensured.

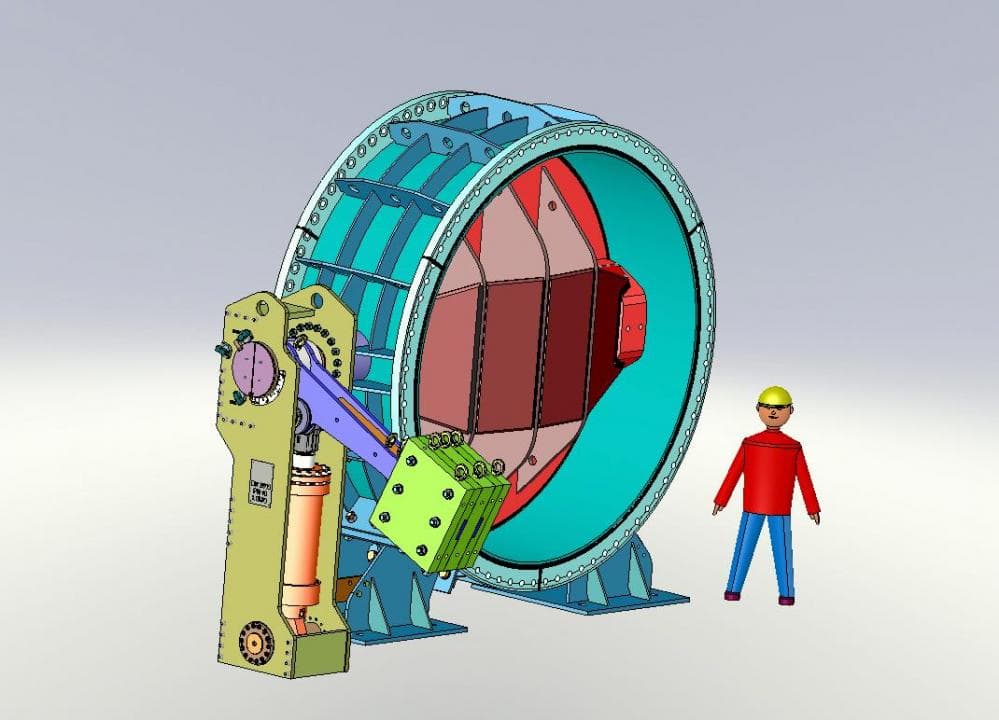

Ball valves K92 AG

The company ARMATURY Group produce huge range of ball valves in diameter from DN 100 up to DN 1400. The highest pressure that the company produced was PN 160. That means that the valve must stand water column approx. 1600 m.

Since the working medium is water, there is bigger claim on material, what are not succumb to the corrosion. We use stainless steel or other materials with surface treatment. On the ball for bigger hardness is coating with nickel and silicon and on the cover is under the seat stainless steel overlay. The whole inner part is protected from corrosion with coating.

Every piece is original

If the customer orders a valve controlled by counterweight and hydraulic cylinder it is in 99 % prototype. It is from the reason, that every control is based on the customer. The customer must give us the water gradient (between upper and bottom tank), the pressure of the oil in the hydraulic cylinder, water flow, difference between the pressure in front and behind the valve.

All these parameters effect the size of the counterweight and hydraulic cylinder. The counterweight weights up to several tons at higher diameters. That mean, then even though two ball valves have the same DN and PN, they can be totally different and at the end we have two totally different products.

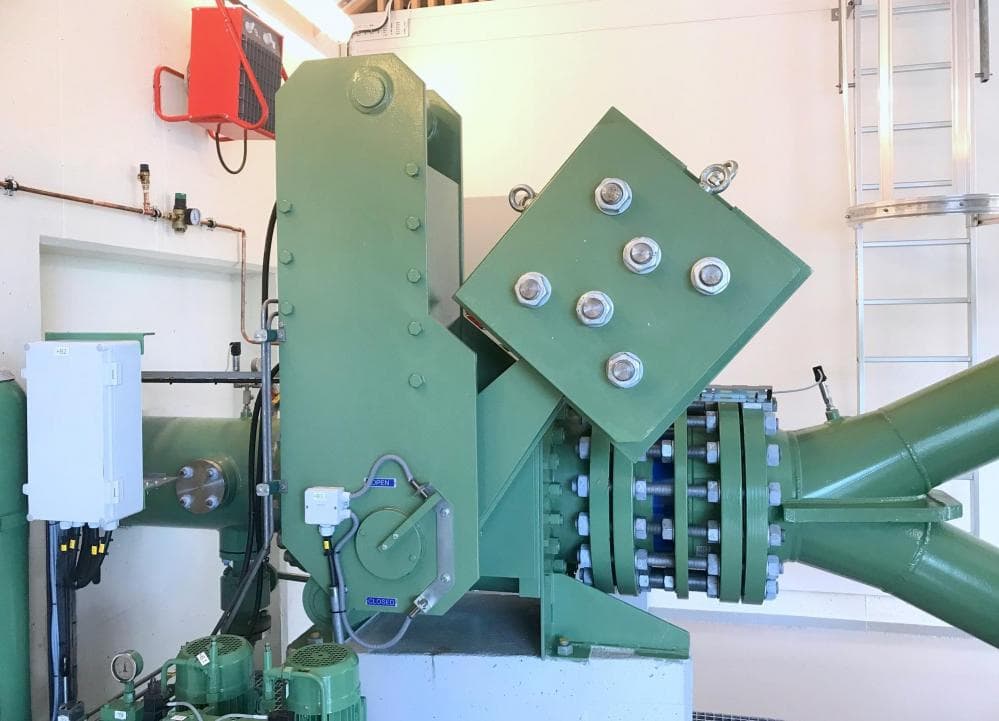

Butterfly valves L32 AG

For this application are mostly use the butterfly valves type L32.7, where the disc with double eccentricity ensures more favorable closing moments. The weight of the counterweight is in this case smaller, than using the butterfly valve with a disc set in one direction only.

The first safety valve was produced in 2001. We manufactured over 430 pieces of these special valves in the pressure from PN 2,5 up to PN 40 and diameter DN 150 up to DN 3500 until last year. The size DN 3500 including the control weights an unbelievable 35 tons!

The butterfly valves for small hydropower plant are comparing to standard catalogue butterfly valves equipped with anchor flap, most of the time they have integrated a by-pass and so is atypical construction length. They can be equipped with integrated dismantling joint, various number of sensors, locking control in end positions and so on.

In addition to the equipment of the valve itself, in some cases there are higher requirements for the test of the welded and semi-finished products. Sometimes it is necessary to extend the documentation with more detailed drawings, strength calculation, flow characteristic and other…

Huge range of accessories

Very often are these valves, both butterfly valves and ball valves, supplied with other devices, such as dismantling joint and parts of the pipeline serving as an additional measurement. Both can be also equipped with by-pass of the main pipeline, connected for the medium pressure sensor in the pipeline or in the entrance of the pipeline.

Lately customers started to order also anchor frame. This frame is concreted into the floor of the control room and the safety valve is placed on the frame. In some cases, was part of the delivery also hydraulic aggregate, which was placed directly on the valve and it is connected to the hydraulic cylinder by hose. Part of the delivery can be also the system of controls connected to the sensor, which controls the parameters of the medium.

We are receiving more and more orders for safety valves for small hydropower plants. The construction of those power plants is completely in accordance with the current direction of electricity production without an ecological burden on our planet.

At ARMATURY Group, we are glad that we can be part of this process. We are trying to accomplish customer’s wishes and requirements so they will be happy to come back to us. The idea of sustainable development is at the beginning of every order and it is a common goal of our customers also.

For more information:

Petr Heider, technical director