Metallurgical valves in 2022 and in the future

The year 2022 is a breakthrough year for the segment of metallurgical valves in ARMATURY Group a.s.

As you have already been informed, at the beginning of the year, a separate business group was established under the leadership of Sami Leinonen to provide sales and services to metallurgical companies all around the world.

To support the activity of this department, the new was created. This catalogue is conceived completely differently than all previous editions. It is a comprehensive overview of special valves manufactured for metallurgical plants, without dimensional tables and detailed descriptions. Catalogue sheets will be sent to customers in case of their interest in a specific type of valve. The new catalogue also includes new types of valves and, above all, considers the investment in a new machining centrum, which enables us to produce even larger valve dimensions in metallurgical valves.

News in the field of metallurgical valve

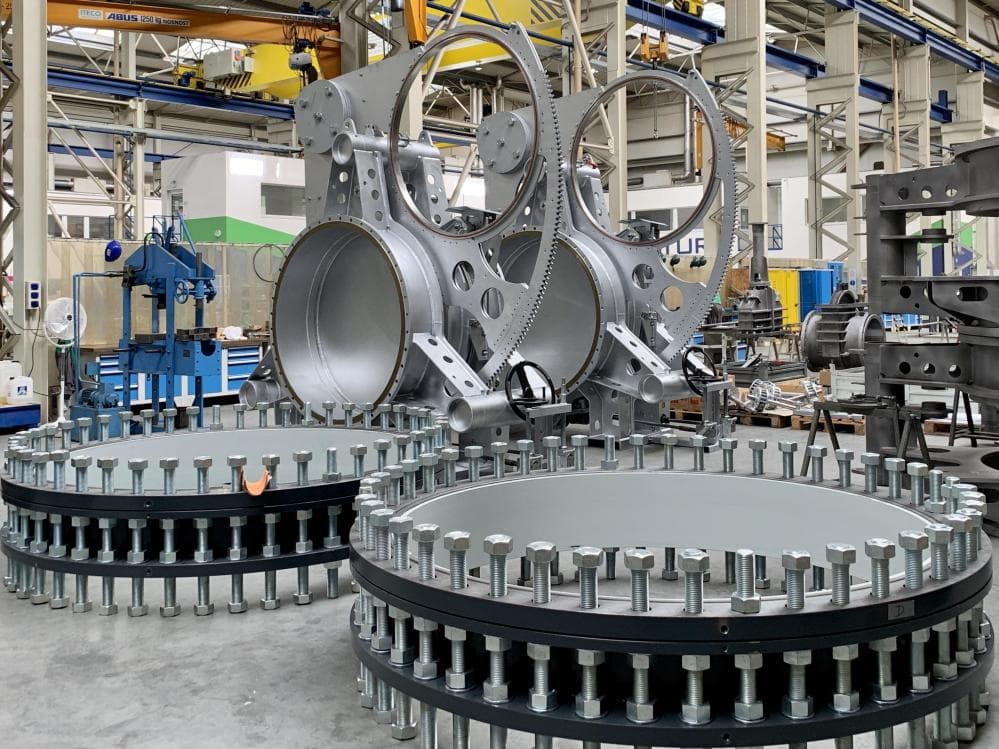

- hot-blast gate valve – C63.6 type 136 – extension to DN 2000

- two lever valve – C61.4 113 type 141 – extension to DN 3000

- three lever valve – C61.4 type 141A – new type of butterfly valve

- environment friendly goggle valve – C62.2 type 129A – extension to DN 3000, replacing type 129B

- environment friendly goggle valve – C62.3 type 139 – extension to DN 3000

- three-eccentric butterfly valve – C61.3 type 140A – extension to DN 2000

- control valve – C65.1 type 124 – extension to DN 4000

Development in the future

In the coming period, ARMATURY Group intends to focus on expanding its cooperation with end customers and project organizations, especially in Western Europe. The company focuses on customized modifications of individual types of valves. Its specialists and experts always look for the best possible technical solution, suitable for the specific operating conditions and needs of the client. Customer feedback is also very important as it helps to continuously improve. ARMATURY Group has an experienced team of technicians who can provide the customer with consultation and advice, which is one of the most needed services, especially when dealing with specific and demanding operational requirements.

In the future, the company plans to expand its valve portfolio with new types of valves that will be needed in new directions of iron production. Reducing the carbon footprint of pig iron production is certainly an important topic for the future and the ARMATURY Group is following new trends and does not want to be left behind in the development of new types of valves.

For more information:

Heider Petr, technický ředitel