We are developing a new type of goggle valve

Vexve Armatury Group has a huge potential in cooperation among companies within the group

Thanks to the synergy projects ARMATURY Group, Vexve, and ZMK Technologies can share their experience and knowledge in the areas of production, sales, marketing, or research and development. And especially in the last-mentioned area we see a huge potential in providing critical valve solutions in the transition to a low carbon future.

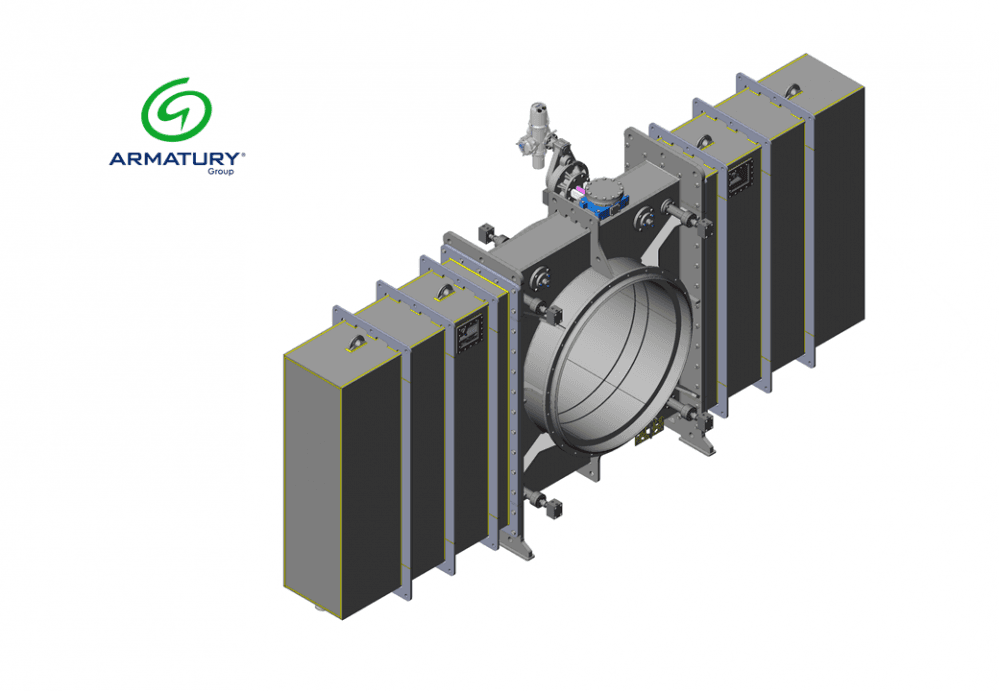

Maximizing synergies is one of the driving forces that move our Group forward. One example is the development of the new C62.3 type 139Z DN 2000 goggle valve for the demanding environment of petrochemicals.

Project of goggle valves for petrochemicals

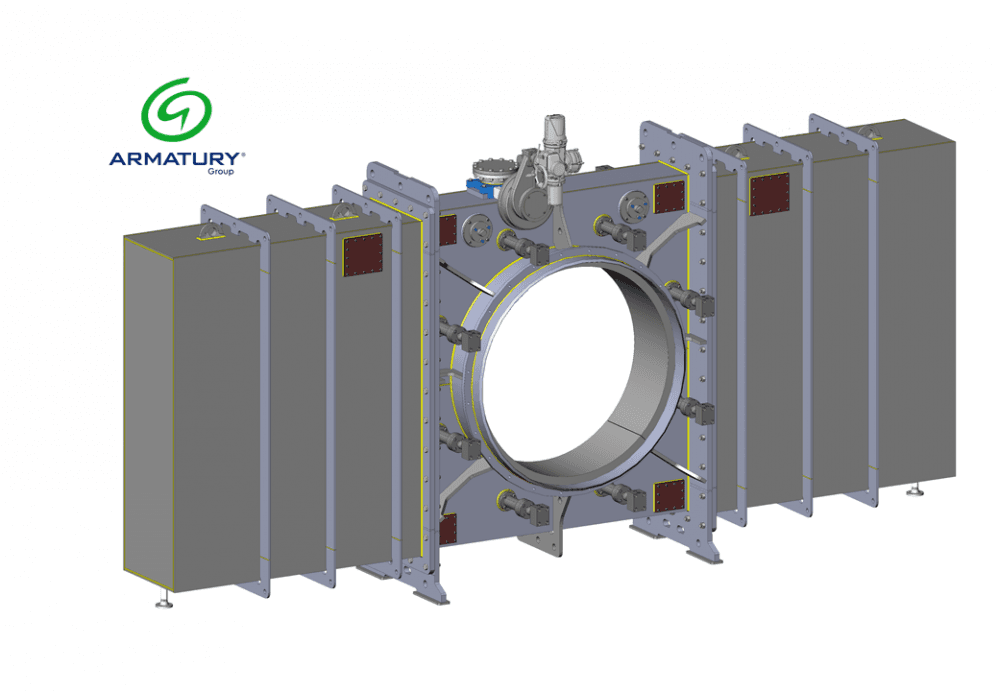

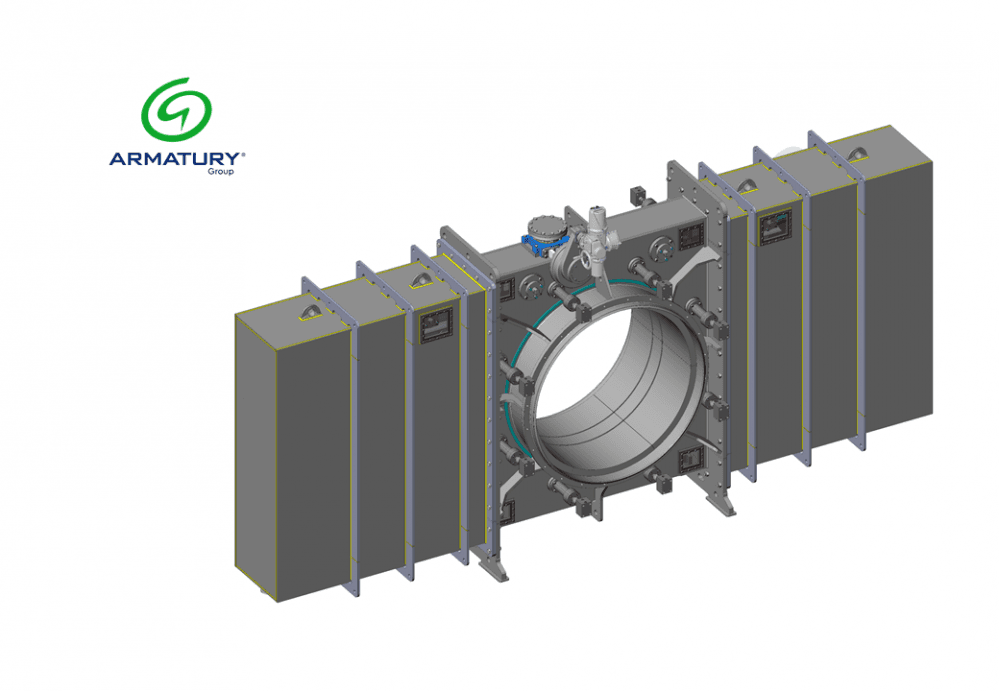

Our goal is to develop a new type of goggle valve C62.3 type 139Z for the demanding petrochemical environment. Due to the high temperature and aggressiveness of the working medium, we had to use special materials and fireproof lining for the prototype of DN 2000. The valve is designed for the end customer in two versions, according to EN and ASME standards.

In this project, the designers and technicians of ARMATURY Group and ZMK Technologies work together and their goal is to extend the range of valves for petrochemistry with a new, highly specialized type of valve, which is currently Vexve Armatury Group does not offer.

Valve technical specifications

The valve is designed for installation into a horizontal pipeline with frame movement also in a horizontal direction. The working medium may be flue gas with impurities with a working temperature of 780 °C, which can increase in short term up to 900 °C, working pressure 0,2 bar. Due to the high temperature of the medium, the valve bore is provided with special insulation and fireproof lining. The transfer of the frame with eyes from the seat is done by special hydraulic units located outside the body, the movement of the gate for the open and closed condition is provided by an electric actuator with a gearbox.

This type of valve is used as a standard in refineries at FCC units to close flue pipes due to maintenance or shutdown operation. The valve is also designed for the emergency closure of the pipeline in the event of an emergency.

The design of the prototype is finishing

The first two stages of the project were completed last year. The first stage focused on market research and specifications; in the second stage, the complete 3D model of the valves was realized. This year we prepared complete production documentation, performed strength and temperature calculations, prepared production and welding technology, and developed production procedures.

We are pleased to present you with a new product, which development is coming to the end. We believe that the new type of goggle valve will bring added value to its future customers in the form of maintenance-free operation with long service life.

For more information:

Pavel Heider, designer