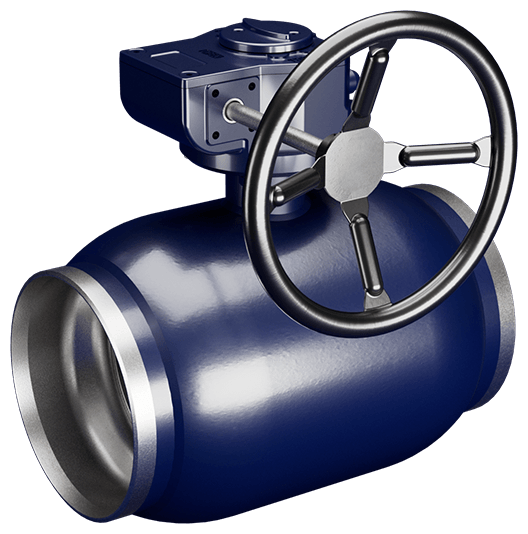

Vexve butterfly valves

Available in sizes from DN 300 to DN 1600

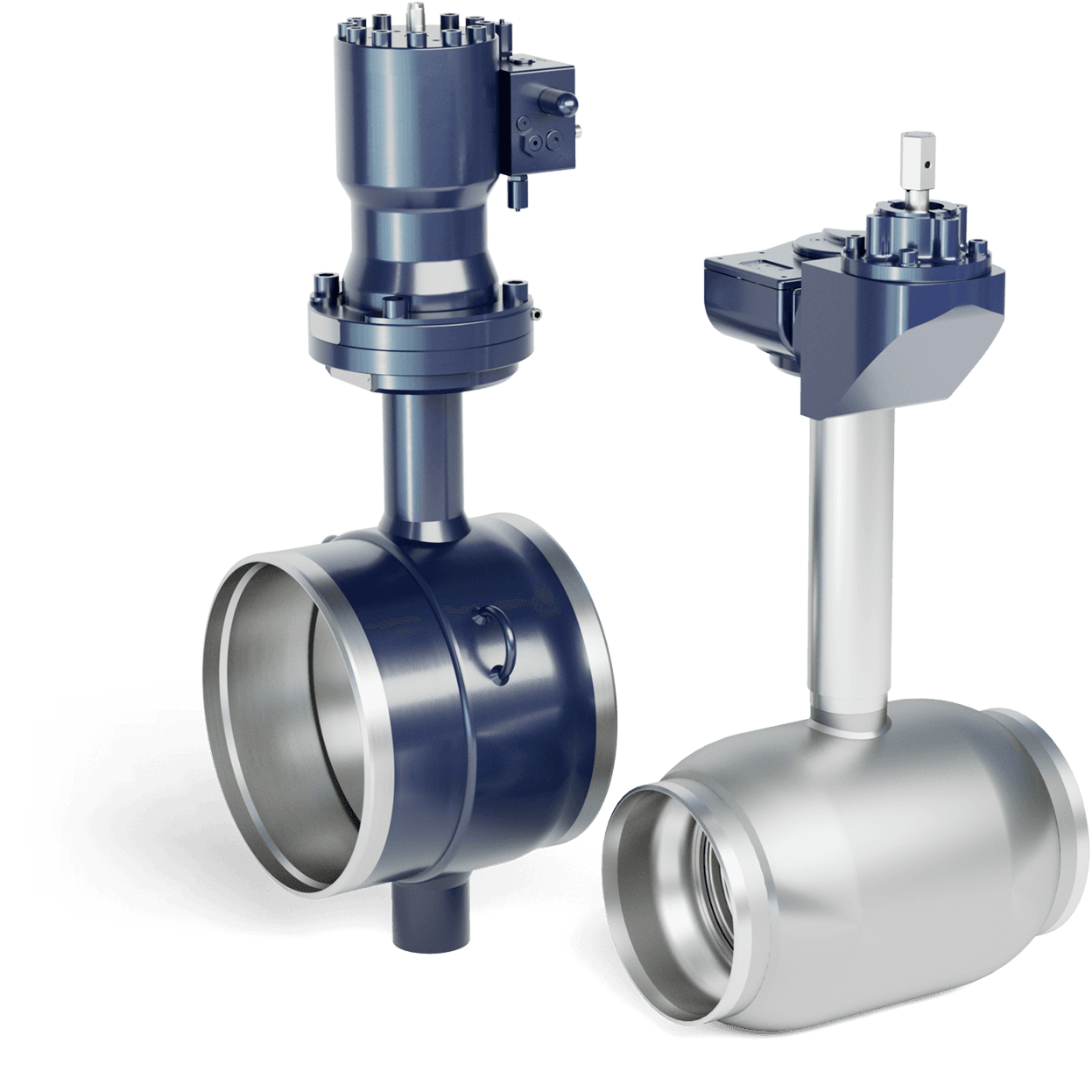

Shut-off butterfly valves

DN 300–1400

Control and shut-off butterfly valves

DN 300–1200

Downloads

From the download center, you can find our company and product certificates, operation manuals, our general brochures and company-related media material in addition to tender specifications.

Valve finder

Find the right valve solution for you by using our valve finder

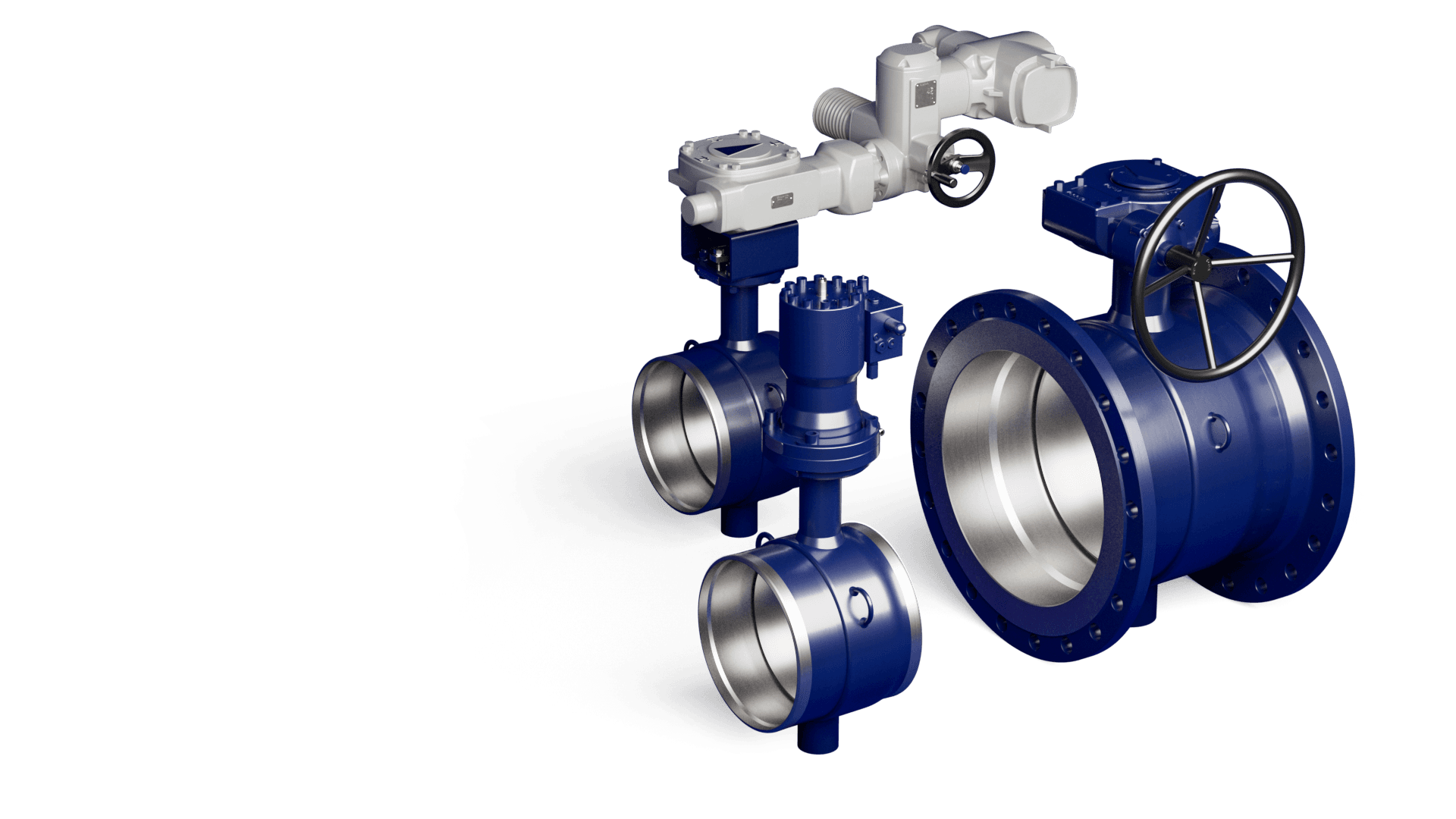

Butterfly valve features

Optimal flow properties for all most demanding applications

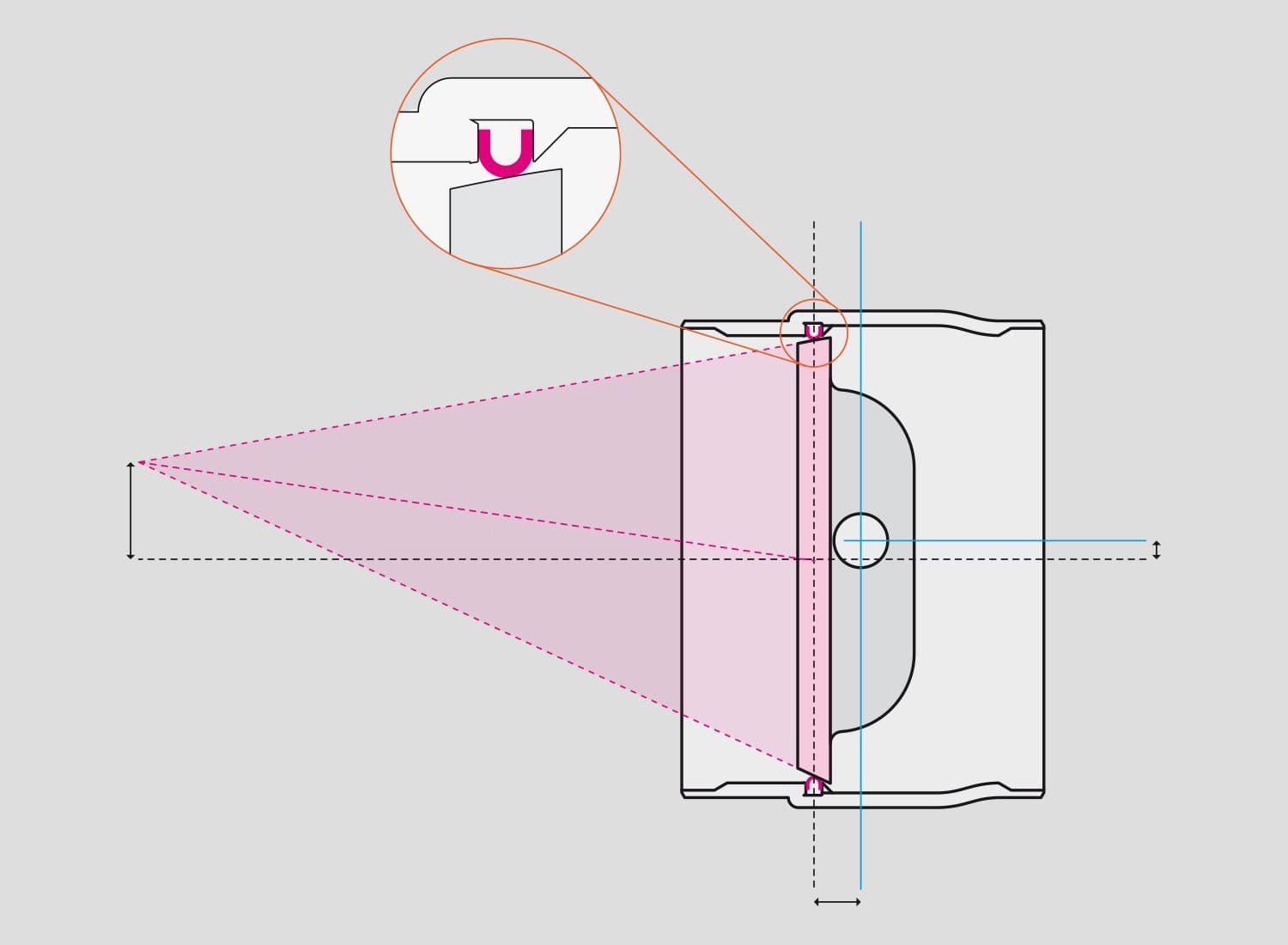

- disc and stem structure minimizes flow resistance and turbulence

- strong two-piece stem structure maximizes flow capacity

- full-bore structure in size classes DN 300–800

- particularly high Kv value in DN 900 to 1600 reduced bore butterfly valves

- high Kv value reduces pumping costs

All metal seat construction

- metal seals extend the lifetime of the butterfly valve

- suitable for many different applications and withstands varying water quality

- total tightness in both flow directions

- practically maintenance-free

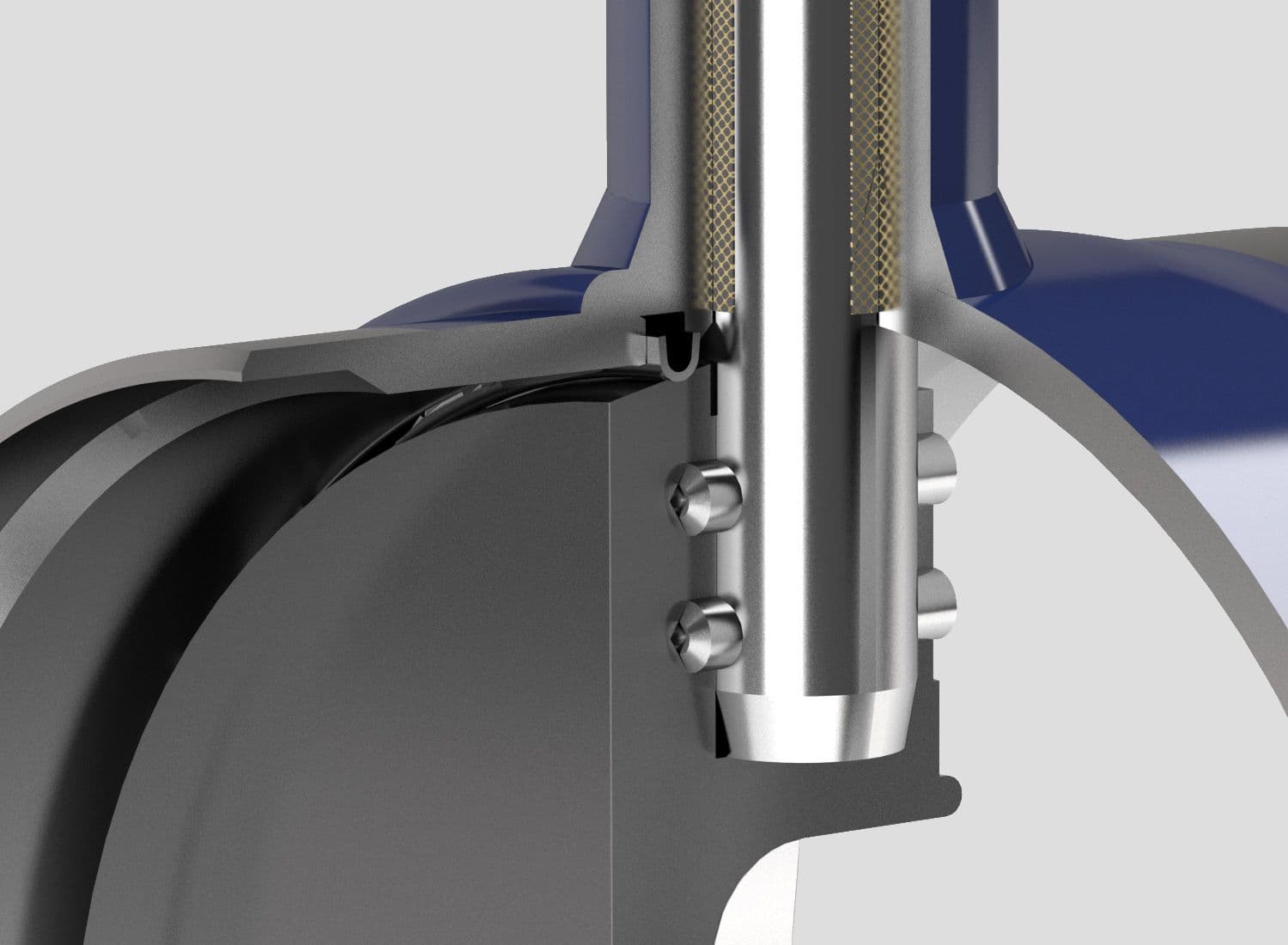

Triple offset geometry design

- minimizes the friction between the disc and seat ring during operation

- prevents wear and ensures long service life of the valve

Butterfly valve main characteristics

Applications

district heating networks

district cooling networks

Available

as shut-off butterfly valve or control and shut-off butterfly valve

in sizes from DN 300 to DN 1600

with full bore or reduced bore

in pressure class PN25 (body)

in trim classes Δp=16 bar or Δp=25 bar

with tightness class A or B (EN12266-1)

for a temperature range of −40°C to 200°C (250°C)

with weld connections EN (DIN) together with GOST standards (recommended)

also with flanged connections

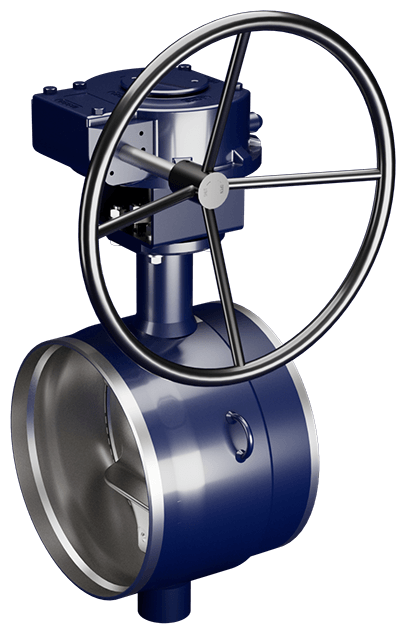

with manual gear, electric or hydraulic actuator

Characteristics

fully welded construction

manufactured using high quality materials and components

light weight, space saving design

easy-to-insulate

easy-to-install and operate

maintenance-free

metal seated

stainless steel disc+ special alloy chrome plated seat

triple offset geometry

total tightness in both flow directions

non-jamming seat construction

seat design for large temperature ranges

high Kv value

designed according to EN488

Find your nearest distributor